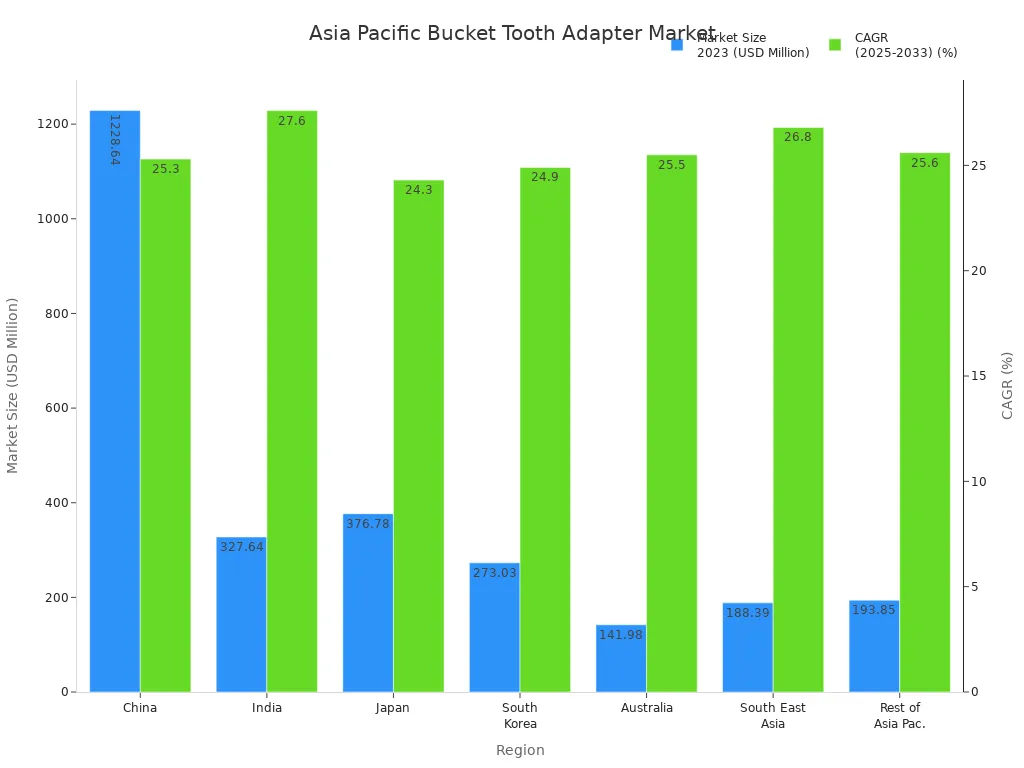

Heavy equipment operators in Asia Pacific drive demand for the latest bucket tooth adapter technology, as shown below:

| Region | Market Size 2023 (USD Million) | CAGR (2025-2033) (%) |

|---|---|---|

| China | 1228.64 | 25.3 |

| India | 327.64 | 27.6 |

| Japan | 376.78 | 24.3 |

| South Korea | 273.03 | 24.9 |

| Australia | 141.98 | 25.5 |

| South East Asia | 188.39 | 26.8 |

| Rest of Asia Pac. | 193.85 | 25.6 |

| Total Asia Pacific GET Market | 2730.31 | 25.8 |

Industry leaders select bucket tooth adapter systems based on durability, compatibility, and performance. High-wear bucket tooth pins, bucket pin and lock, and bucket pin and lock sleeve of excavator ensure reliable connections. Bucket tooth pins for mining excavators maximize uptime in tough conditions.

Key Takeaways

- Choose bucket tooth adapters that fit your machine and job needs to improve performance and reduce wear.

- Top adapters for 2025 include CAT J300, Komatsu PC200, and ESCO Super V, each offering strong durability and unique features.

- Regular inspection and proper installation of adapters extend their life and help avoid costly downtime.

Bucket Tooth Adapter Quick Comparison Table

Top Bucket Tooth Adapter Picks for 2025

Operators and fleet managers continue to seek reliable solutions for their heavy equipment. The following adapters stand out as the top choices for 2025:

- CAT J300 Series Adapter

- Komatsu PC200 Adapter

- ESCO Super V Adapter

- QUANZHOU DINGTAI Engineering Adapter

These options deliver strong performance in demanding environments. Each adapter offers unique features that address specific job site needs.

Key Specs and Ratings

The table below highlights the main specifications and ratings for the leading bucket tooth adapters in 2025:

| Model | Material | Fitment Range | Installation | Avg. User Rating (2025) |

|---|---|---|---|---|

| CAT J300 Series | Alloy Steel | 20-30 ton machines | Weld-on | 4.8/5 |

| Komatsu PC200 | High-Strength Steel | 18-25 ton machines | Bolt-on | 4.7/5 |

| ESCO Super V | Alloy Steel | 15-35 ton machines | Pin & Lock | 4.6/5 |

| QUANZHOU DINGTAI Engineering | Alloy Steel | 20-30 ton machines | Weld-on | 5.0/5 |

Note: The QUANZHOU DINGTAI Engineering bucket tooth adapter receives an average user rating of 5.0 out of 5 in 2025. This high score reflects strong customer satisfaction and positive feedback from operators.

These ratings help buyers compare options quickly and select the best fit for their equipment and job requirements.

What to Look for in a Bucket Tooth Adapter

Durability

Durability stands as a top priority for any bucket tooth adapter. Material properties such as hardness, toughness, and fracture toughness play a major role. High manganese steel and alloy steel are common choices. High manganese steel increases surface hardness under impact and offers good toughness, making it suitable for heavy-duty work. Alloy steel provides higher wear resistance but usually costs more. Forging and heat treatments like quenching and tempering improve strength and toughness. Surface coatings, such as ceramic or galvanizing, help protect against wear and corrosion.

Compatibility

Operators must ensure the adapter matches their equipment. Compatibility depends on the loader or excavator model, tooth design, and attachment system. For example, some adapters fit only specific brands or models, while others, like H&L-style 230 adapters, work across several brands. Using the correct adapter reduces premature wear and keeps equipment running efficiently.

- Replacement adapters must fit the loader or excavator model.

- Adapters come in different configurations for various tooth designs.

- Proper fitment maintains durability and performance.

Ease of Installation

Efficient installation saves time and reduces downtime. The best practice involves positioning the bucket safely, cleaning all parts, and using the correct pin and retainer. Precision tools help measure and confirm fitment. Regular inspection ensures secure attachment and maximizes wear life.

Tip: Always check pin types and retainer sizes before installation to prevent early wear.

Cost-Effectiveness

Cost matters for every operation. In 2025, high-quality adapters usually cost between $2 and $40 each, depending on type and order size. Bulk orders lower the price per piece. Premium sets with longer life may cost more but offer better value over time.

| Product Type | Price Range (USD) |

|---|---|

| Standard adapters | $2 – $40 |

| Premium/specialized sets | $20 – $45 |

Performance in Different Conditions

A bucket tooth adapter must perform well in various environments, from rocky ground to wet clay. High hardness improves wear resistance, while good toughness prevents breakage. Surface treatments and proper fitment help adapters last longer, even in harsh conditions.

In-Depth Reviews of the Best Bucket Tooth Adapter Options for 2025

CAT J300 Series Bucket Tooth Adapter Overview

The CAT J300 Series bucket tooth adapter stands out as a reliable choice for heavy equipment operators. This adapter uses advanced alloy steel and a casting process that ensures strength and durability. Ningbo Digtech (YH) Machinery Co.,Ltd. manufactures this product to meet or exceed OEM standards, making it a trusted option for many construction and mining projects. The adapter fits a wide range of excavators, loaders, and bulldozers from leading brands.

CAT J300 Series Key Features

| Feature | Description |

|---|---|

| Material | Alloy steel |

| Production Method | Casting (Wax-lost, Sand-coated) |

| Hardness | Approximately 51-54 HRC (up to 52 HRC) |

| Tensile Strength | ≥ 1450 to 1500 N/mm² |

| Impact Toughness | ≥ 15J to ≥ 20J (measured at 25ºC) |

| Yield Strength | ≥ 1100 Re N/mm² |

| Design Features | Innovative design to increase life and efficiency; balance between hardness and toughness |

| OEM Compliance | Manufactured to meet or exceed OEM sizes and specifications |

| Application | Compatible with all brand excavator bucket teeth |

| Additional Notes | Products are stronger and last longer than comparable teeth on the market |

This table highlights the robust construction and thoughtful design of the CAT J300 Series adapter.

CAT J300 Series Pros & Cons

Pros:

- High durability and wear resistance

- Strong mechanical properties for tough jobs

- Fits many brands and models

- Manufactured to strict quality standards

Cons:

- Premium price compared to some alternatives

- May require skilled installation for best results

CAT J300 Series Ideal Use Cases

Operators use the CAT J300 Series bucket tooth adapter in many settings:

- Excavators, bulldozers, and loaders from Caterpillar, Hitachi, Komatsu, and Kobelco

- Wheel loaders such as 966G, 966H, 972G, and 972M

- Construction, mining, grading, and hauling tasks

This adapter works well for both general earthmoving and heavy-duty mining.

CAT J300 Series User Feedback

Users report that the CAT J300 Series bucket tooth adapter delivers high durability and reduces maintenance costs. Many praise its efficiency and easy installation. Operators in mining and construction note the product’s strong performance and long service life. The adapter’s design increases profitability and safety on job sites. Customers also value the consistent quality provided by Ningbo Digtech (YH) Machinery Co.,Ltd.

Komatsu PC200 Bucket Tooth Adapter Overview

The Komatsu PC200 bucket tooth adapter is engineered for strength and longevity. It uses high-grade wear plates and materials like Hardox and Bisalloy, making it much stronger than mild steel. The adapter is produced using advanced welding and casting techniques, which improve toughness and crack resistance. This product is a popular choice for Komatsu PC200 excavators in demanding environments.

Komatsu PC200 Key Features

| Feature | Details |

|---|---|

| Material | Ductile iron, gray iron, carbon steel, low alloy steel |

| Surface Hardness | 470-540 HRC |

| Hardness & Impact Values | 48-52 HRC, Impact >15J to >20J |

| Casting Methods | Sodium silicate sand, resin sand, EPC lost foam, “V” process |

| Surface Treatments | Painting, polishing, heat treatment, planing |

| Machining Processes | Lathe, CNC, drilling, milling, boring, planing |

| Welding Techniques | Mixed gas arc welding (MAG), carbon dioxide welding (FCAW) |

| Product Types | Standard, rock chisel, penetration, heavy duty |

| Quality & Certification | ISO9001:2008, ISO/TS16949, OEM customization |

| Application Compatibility | Designed for Komatsu PC200 excavators |

Komatsu PC200 Pros & Cons

Pros:

- Superior wear resistance and long service life

- Multiple product types for different job needs

- Strong structural design with advanced welding

- Quality certifications and OEM customization

Cons:

- Best suited for Komatsu PC200 models, limiting cross-brand use

- May be over-engineered for light-duty applications

Komatsu PC200 Ideal Use Cases

Operators choose the Komatsu PC200 bucket tooth adapter for:

- Earthmoving, mining, and construction projects

- Applications with rock chisel, standard, or penetration teeth

- Environments with soil, sand, stone, or mixed materials

The adapter performs best in tough conditions that require high durability.

Komatsu PC200 User Feedback

Users appreciate the Komatsu PC200 adapter’s strong mechanical properties and wear resistance. Many report improved excavation efficiency and longer service life, especially in soft to medium-hard materials. The reinforced variants handle harder soils and mixed materials well. Customers value the product’s reliability and the rigorous quality control during manufacturing.

ESCO Super V Bucket Tooth Adapter Overview

The ESCO Super V bucket tooth adapter features a unique design that boosts strength and durability. Its super V shape allows for easy installation with standard tools, making it accessible for many users. The adapter is built from high-quality alloys and is suitable for demanding excavation tasks. Ningbo Digtech (YH) Machinery Co.,Ltd. distributes this product, ensuring consistent supply and support.

ESCO Super V Key Features

- Made from superior, heat-treated alloys for maximum strength

- Hammerless lock system for safe and quick installation

- Contoured shapes for better penetration and material flow

- Compatible with most excavator buckets

- Designed for heavy-duty construction and mining

ESCO Super V Pros & Cons

Pros:

- Simple installation with no special tools required

- Long wear life and high reliability

- Improved safety due to hammerless lock system

- Consistent performance across many applications

Cons:

- Higher initial cost than some alternatives

- Limited explicit drawbacks reported by industry experts

ESCO Super V Ideal Use Cases

The ESCO Super V bucket tooth adapter is recommended for:

- Excavator buckets in construction, trenching, and landscaping

- Rocky terrain, quarrying, and mining operations

- Jobs that require breaking up rocks or digging trenches

Its robust design makes it suitable for the toughest job conditions.

ESCO Super V User Feedback

Customers recognize the ESCO Super V bucket tooth adapter for its durability and value. Many note that while the product is not the cheapest, its quality justifies the investment. Users describe it as reliable and free from defects. The adapter’s reputation benefits from ESCO’s global leadership in ground engagement tools and the support of Ningbo Digtech (YH) Machinery Co.,Ltd. Operators report that the product meets their needs and performs well in the field.

How to Choose the Right Bucket Tooth Adapter for Your Equipment

Matching Bucket Tooth Adapter to Machine Type

Selecting the right bucket tooth adapter starts with matching it to the machine. Operators should check that the adapter and bucket teeth are compatible. This prevents early wear or breakage. The size, shape, and profile of the adapter must fit the machine and digging conditions. A good match improves penetration and productivity. Operators should also balance hardness and impact strength to avoid downtime. Supply availability matters, so choosing adapters with strong supplier support helps with inventory and maintenance. Safety features, such as hammerless systems, make changing teeth easier and safer. The type of adapter—pin-on, weld-on, or locking pin—should fit the machine’s needs and maintenance style.

- Confirm compatibility with machine and bucket teeth

- Match size and profile to digging conditions

- Choose adapter type based on maintenance needs

- Check for supplier support and safety features

Assessing Job Requirements

Job requirements shape the choice of adapter. Soil type affects which adapter works best. Softer soils need penetration teeth, while rocky or abrasive soils require more durable adapters. The machine’s workload, such as tonnage and digging force, determines the size and profile needed. Operators should consider the fixing system and tooth pocket shape for a secure fit. Consulting manufacturers helps match the adapter to the job and manage costs.

| Factor | Influence on Adapter Choice |

|---|---|

| Tooth Size | Larger sizes suit higher machine tonnage and digging force |

| Tooth Profile | TIGER for rocky ground, penetration for clay, heavy-duty for abrasive terrain |

| Application | Profiles differ for excavators and loaders, based on terrain and wear resistance |

| Fixing System | Horizontal, vertical, or bolted systems affect fit and durability |

| Material Hardness | Harder terrain needs adapters with greater wear and impact resistance |

| Machine Model | Determines suitable adapter system for workload and soil |

Maintenance Tips for Bucket Tooth Adapters

Proper maintenance extends the life of a bucket tooth adapter. Operators should clean adapters regularly to remove dirt and debris. Lubrication at contact points reduces friction. Align adapters with bucket teeth to prevent uneven wear. Regular inspections help spot rust, loose bolts, or misalignment early. Using only compatible bolts and adapters ensures a proper fit. Operators should replace worn or damaged parts quickly to keep equipment running smoothly.

Tip: Store equipment in dry, covered areas and use anti-corrosion sprays to prevent rust.

Bucket Tooth Adapter Frequently Asked Questions

Operators and buyers often have questions about bucket tooth adapters. Many want to know why teeth fall off during use. Most tooth loss happens because the adapter wears out, not the tooth itself. A proper fit between the tooth and adapter helps prevent this problem. When teeth become worn, operators replace them to protect the adapter. This step saves money because adapters cost more to replace than teeth. The frequency of tip changes depends on the digging material. Abrasive ground causes faster wear. Regular replacement of worn teeth improves production and lowers fuel use.

Here are some of the most common questions:

- What brands of adapters and tips offer the best quality? Are there big differences between brands?

- Can operators use tips from different brands or aftermarket sources on the same adapter?

- When should adapters be replaced—only at the end of their life or during a full bucket rebuild?

- How often do operators change tips, and how does the digging material affect this?

- Are there supply issues with certain brands right now?

- Why do some operators switch from OEM to aftermarket brands like ESCO or Black Cat?

- How much research do buyers do before changing brands or parts?

- What are the pros and cons of hammerless retention systems compared to pin systems?

Tip: Operators should always check the fit and retention system before installing a new bucket tooth adapter. This step helps avoid early wear and keeps equipment running smoothly.

| Adapter Model | Best For | Lifespan (hrs) | Key Benefit |

|---|---|---|---|

| CAT J300 | Mixed fleets, general use | 400-800 | Broad compatibility |

| ESCO Super V | Mining, demolition, heavy-duty | 600-1200 | Low wear, high durability |

| Komatsu PC200 | Komatsu excavators, tough jobs | 500-900 | Superior wear resistance |

- Operators should select a bucket tooth adapter that matches their machine and job site.

- Regular inspections and timely replacements help maintain digging efficiency and reduce downtime.

- Choosing the right adapter system lowers operational costs and extends equipment life.

FAQ

What causes bucket tooth adapters to wear out quickly?

Operators often see rapid wear from abrasive materials, improper fit, or lack of regular maintenance. Frequent inspections and correct installation help extend adapter life.

Can aftermarket bucket tooth adapters match OEM quality?

Many aftermarket adapters meet or exceed OEM standards. Operators should check for certifications and user reviews before purchasing. Quality varies by manufacturer.

How often should operators replace bucket tooth adapters?

Replacement depends on usage and soil conditions. Most adapters last 400–1200 hours. Regular checks help operators spot wear early and avoid unexpected downtime.

Tip: Operators should always inspect adapters during routine equipment maintenance for best performance.

Post time: Jul-11-2025