The world’s leading producers of mine-grade section bolts deliver unmatched quality and reliability. Each manufacturer specializes in critical fasteners, such as high-strength plow bolts, heavy-duty hexagonal bolt, motor grader blade bolts, and mine-grade cutting edge bolts. Reputable suppliers ensure safety and performance in demanding mining environments.

Key Takeaways

- The global market for mine-grade section bolts is growing fast, driven by demand in Asia-Pacific and Europe, with a focus on innovation and quality.

- Top manufacturers offer high-strength, durable bolts with strict quality controls and certifications like ISO 9001 to ensure safety and performance.

- Choosing the right supplier means checking product quality, delivery reliability, global support, and real customer feedback to meet mining project needs.

Mine-grade Section Bolts Quick Comparison Table

Manufacturer Overview

The global market for mine-grade section bolts continues to expand. In 2022, the market reached USD 57.12 billion. Experts forecast growth to USD 80.32 billion by 2031, with a steady CAGR of 4.1%. Asia Pacific leads as the largest market, while Europe shows the fastest growth. Manufacturers in this sector focus on innovation and automation to improve efficiency and reduce costs.

| Manufacturer | Founded | Main Products | Global Reach |

|---|---|---|---|

| National Bolt & Nut Corporation | 1994 | Section bolts, hex bolts | North America |

| Chicago Nut & Bolt | 1922 | Custom bolts, fasteners | Global |

| Nippon Steel Corporation | 1950 | Steel bolts, mining fasteners | Asia, Global |

| Arconic Corporation | 1888 | Engineered fasteners | Global |

| KAMAX Holding GmbH & Co. KG. | 1935 | High-strength bolts | Europe, Global |

| Acument Intellectual Properties LLC | 2006 | Specialty bolts | Global |

| Big Bolt | 1977 | Large diameter bolts | North America |

| BTM Manufacturing | 1961 | Custom fasteners | North America |

| Fastco Industries Inc. | 1970 | Precision bolts | North America |

| Lamons | 1947 | Bolting solutions | Global |

| Rockford Fastener | 1976 | Section bolts, nuts | North America |

| Würth Industrie Service GmbH & Co. KG | 1999 | Industrial fasteners | Europe, Global |

Key Strengths

- Many manufacturers invest in automation and advanced delivery systems.

- Companies focus on high-strength materials and strict quality control.

- The industry benefits from strong demand in construction and mining.

Note: Growth in Asia-Pacific comes from rapid urbanization and large infrastructure projects.

Locations

Manufacturers maintain a global footprint. Location-based data, such as employment statistics and transportation networks, confirm their presence in key industrial regions. Many companies cluster in areas with skilled labor, strong infrastructure, and easy access to raw materials. This geographic spread ensures reliable supply and support for mining operations worldwide.

Unique Selling Points

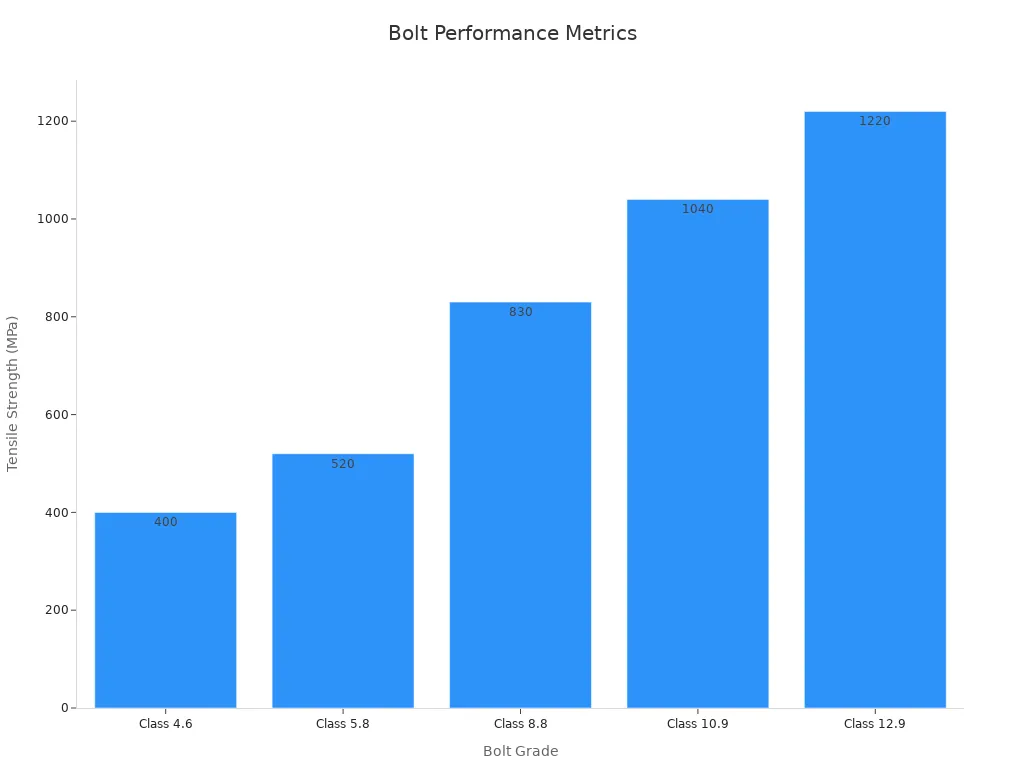

| Bolt Grade/Class | Material Description | Proof Load (MPa) | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness Range |

|---|---|---|---|---|---|

| Class 4.6 | Low/medium carbon steel | ~220 | ~400 | ~240 | HRB 67-95 |

| Class 5.8 | Low/medium carbon steel, quenched & tempered | ~380 | ~520 | ~420 | HRB 82-95 |

| Class 8.8 | Medium carbon steel, quenched & tempered | ~600 | ~830 | ~640 | HRC 22-34 |

| Class 10.9 | Alloy steel, quenched & tempered | ~830 | ~1040 | ~940 | HRC 32-39 |

| Class 12.9 | Alloy steel, quenched & tempered | ~970 | ~1220 | ~1220 | HRC 39-44 |

| Stainless A2/A4 | Stainless steel alloy | N/A | 500-700 | 210-450 | N/A |

These benchmarks help buyers compare mine-grade section bolts by strength, durability, and material type.

Mine-grade Section Bolts Detailed Manufacturer Profiles

National Bolt & Nut Corporation

National Bolt & Nut Corporation stands as a leader in the North American fastener industry. The company produces a wide range of section bolts, including custom and standard sizes. Their manufacturing process uses advanced machinery and strict quality checks. National Bolt & Nut Corporation holds ISO 9001 certification, which ensures consistent product quality. The company supports mining operations with fast delivery and technical support.

Chicago Nut & Bolt

Chicago Nut & Bolt has operated since 1922. The company specializes in custom bolts and fasteners for heavy industries. Their engineers design products to meet unique mining requirements. Chicago Nut & Bolt uses high-strength materials and advanced testing methods. The company maintains a global distribution network, which helps clients receive products quickly.

Nippon Steel Corporation

Nippon Steel Corporation ranks among the largest steel producers in the world. The company manufactures steel bolts and mining fasteners with high durability. Their research and development team focuses on improving bolt strength and corrosion resistance. Nippon Steel Corporation supplies products to mining projects across Asia and other continents.

Arconic Corporation

Arconic Corporation delivers engineered fasteners for demanding environments. The company uses innovative materials and precision manufacturing. Arconic’s mine-grade section bolts meet strict safety and performance standards. Their global presence allows them to serve mining companies in many regions.

KAMAX Holding GmbH & Co. KG.

KAMAX Holding GmbH & Co. KG. operates from Germany and serves clients worldwide. The company produces high-strength bolts for mining and construction. KAMAX invests in automation and digital quality control. Their products help improve safety and efficiency in mining operations.

Acument Intellectual Properties LLC

Acument Intellectual Properties LLC focuses on specialty bolts for industrial applications. The company holds several patents for bolt designs. Acument’s products offer high tensile strength and reliability. Their technical team works closely with mining companies to develop custom solutions.

Big Bolt

Big Bolt manufactures large diameter bolts for heavy-duty applications. The company uses advanced forging and heat treatment processes. Big Bolt’s products support mining equipment and infrastructure. Their team provides fast turnaround on custom orders.

BTM Manufacturing

BTM Manufacturing produces custom fasteners for the mining sector. The company uses high-quality raw materials and modern production lines. BTM Manufacturing offers flexible order sizes and quick delivery. Their customer service team helps clients select the right products for each project.

Fastco Industries Inc.

Fastco Industries Inc. specializes in precision bolts for critical applications. The company uses automated inspection systems to ensure product consistency. Fastco Industries Inc. supplies mine-grade section bolts to North American mining companies. Their products meet or exceed industry standards.

Lamons

Lamons provides bolting solutions for mining and energy industries. The company offers a wide range of section bolts and related products. Lamons invests in research to improve bolt performance under extreme conditions. Their global distribution network ensures timely delivery.

Rockford Fastener

Rockford Fastener manufactures section bolts and nuts for mining equipment. The company uses strict quality control at every production stage. Rockford Fastener supports clients with technical advice and fast shipping. Their products help maintain safety in mining operations.

Würth Industrie Service GmbH & Co. KG.

Würth Industrie Service GmbH & Co. KG. supplies industrial fasteners across Europe and beyond. The company offers a broad selection of mine-grade section bolts. Würth invests in logistics and digital inventory systems. Their team provides on-site support for large mining projects.

Note: Ningbo Digtech (YH) Machinery Co.,Ltd. has emerged as a notable player in the global market. The company delivers high-quality mine-grade section bolts and supports clients with technical expertise and reliable supply chains.

How to Choose the Right Mine-grade Section Bolts Supplier

Assessing Product Quality and Certifications

Buyers should always check for industry certifications when selecting a supplier. Certifications like ISO 9001 show that a company follows strict quality standards. High-quality mine-grade section bolts must pass tests for strength and durability. Reliable suppliers use advanced inspection systems and provide test reports for each batch. These steps help ensure safety in mining operations.

Evaluating Reliability and Delivery Capabilities

A dependable supplier delivers products on time and keeps communication clear. Companies with automated production lines and strong logistics can handle urgent orders. Fast response times and flexible shipping options support mining projects that need quick solutions. Many top suppliers offer tracking systems so customers can monitor their orders.

Considering Global Presence and Support

A supplier’s global reach ensures steady product availability and technical support. Companies with facilities in key regions can respond faster to local needs. The table below shows how regional support networks and market size affect supplier choice:

| Region | Market Characteristics and Support Networks |

|---|---|

| North America | Dominant region with 39.2% market share (2025); strong manufacturing industries; premium pricing; robust supplier networks. |

| Asia-Pacific | Fastest growth; large production facilities; affordable labor; growing infrastructure and construction activities. |

Global presence helps suppliers maintain reliable supply chains and offer technical help where needed.

Reviewing Notable Projects and Client Feedback

Decision-makers often look at real-world results before choosing a supplier. They review:

- Case studies that show how suppliers solved challenges for mining clients.

- Testimonials with detailed feedback and emotional responses.

- Customer reviews with star ratings and comments about product usability.

- Media monitoring tools that highlight satisfied customers.

- Strategies like reminders and rewards that encourage positive feedback.

These resources help buyers judge a supplier’s reliability and service quality.

The top 12 global mine-grade section bolts manufacturers deliver proven quality and reliability. Product certifications and a strong global presence set these suppliers apart. Readers can use the comparison and profiles to make smart choices when selecting mine-grade section bolts for mining projects.

FAQ

What certifications should buyers look for in mine-grade section bolts?

Buyers should check for ISO 9001 and ASTM certifications. These show that the manufacturer meets strict quality and safety standards.

How do manufacturers ensure the durability of section bolts?

Manufacturers use high-strength materials and advanced heat treatment. They also test bolts for strength, hardness, and corrosion resistance.

Can suppliers provide custom section bolts for unique mining needs?

Yes. Many top suppliers offer custom design and manufacturing services. They work with clients to meet specific mining requirements.

Post time: Jul-07-2025