Mining Excavator Bucket Tips play a crucial role in mining operations. Selecting the correct Excavator Bucket Tip or Excavator Bucket Tooth offers tangible benefits, including improved productivity, reduced equipment wear, and enhanced safety.

| Benefit | Result |

|---|---|

| Cost Savings | Lower fuel use and maintenance needs |

| Operator Comfort & Safety | Fewer accidents and less fatigue |

| Precision | Higher quality and less material waste |

Key Takeaways

- Choosing the right bucket tip improves digging efficiency, reduces equipment wear, and enhances safety in mining operations.

- Different bucket tips suit different materials and conditions, such as heavy-duty tips for rocky terrain and flare tips for soft soils.

- Assessing mining conditions and material hardness helps select durable bucket tips that save costs and boost productivity.

Types of Mining Excavator Bucket Tips

Standard Bucket Tips

Standard bucket tips serve as the most versatile option in mining and construction. Manufacturers design these tips with moderate volume and lightweight construction, using high-strength steel and advanced welding techniques. Operators rely on standard bucket tips for general digging, trenching, and material handling tasks. These tips excel in moving ordinary soil, sand, gravel, and clay, making them a default choice for many excavators. Their broad, flat bottom and curved sides provide a balance between digging efficiency and material retention.

Note: Standard bucket tips offer a cost-effective solution for projects that do not require specialized penetration or abrasion resistance. Matching the bucket weight and volume to the excavator’s power prevents overload and ensures long-term durability.

| Feature | Description |

|---|---|

| Material | Heavy-duty steel ensuring durability |

| Shape | Broad, flat bottom with curved sides |

| Sizes Available | Range from 12 to 48 inches and beyond |

| Teeth Options | With or without teeth, depending on task |

Typical Applications:

- General excavation

- Loading and unloading sand, gravel, and clay

- Landscaping and site preparation

Heavy-Duty Bucket Tips

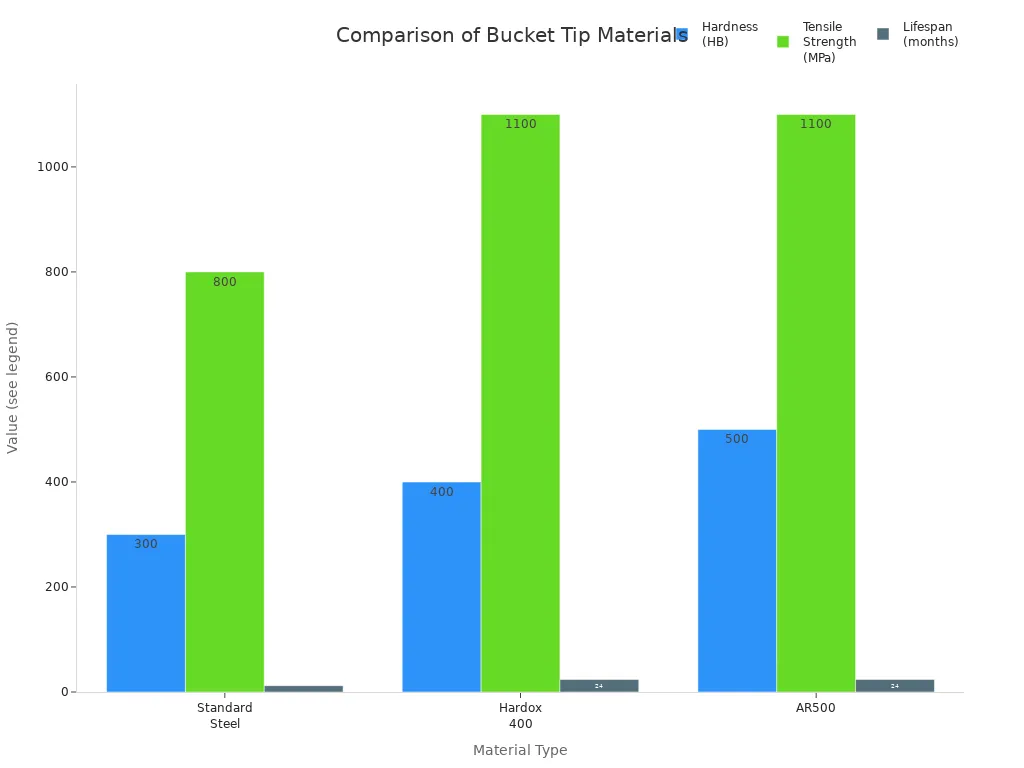

Heavy-duty bucket tips address the challenges of abrasive and rocky mining environments. These tips use thicker steel—typically 15-20mm compared to the 8-12mm found in standard tips—and feature reinforced cutting edges. Manufacturers employ high-grade alloy steels such as Hardox 400 and AR500, which provide hardness ratings of 400-500 Brinell. This composition results in superior wear resistance and a lifespan that can reach up to 24 months, double that of conventional steel tips.

Operators choose heavy-duty bucket tips for digging hard soil, loading crushed rock, and handling gravel. These tips withstand intense abrasion and impact, making them essential for demanding mining operations.

Rock Chisel Bucket Tips

Rock chisel bucket tips, also known as chisel picks, perform best in soft to medium-strength rock formations. These tips handle materials with compressive strengths up to 15-20 MPa, such as coal seams and overburden sand. Open-pit mining operations frequently use rock chisel tips because they require less energy than disc cutters and facilitate simultaneous digging and collecting. Their design allows for efficient excavation in soft rock, making them a standard choice for bucket wheel excavators.

Tiger Bucket Tips

Tiger bucket tips feature a sharp, pointed spike that focuses the excavator’s power on a narrow point. This design delivers superior penetration in hard and compact materials, including tightly packed soils and rocky terrain. Operators use tiger bucket tips when breaking through tough surfaces is a priority. These tips excel in high-impact applications but tend to wear down faster and are less suitable for grading or leveling.

| Tiger Bucket Tip Type | Advantages for Hard and Compact Materials | Key Features |

|---|---|---|

| Single Tiger Teeth | Superior penetration; focuses power | Breaks compact soils and rock; high impact |

| Twin Tiger Teeth | Even greater penetration; V-shaped design | Excels in extremely hard surfaces; high impact |

Twin Tiger Bucket Tips

Twin tiger bucket tips take penetration performance further with a double-pointed, V-shaped design. This configuration enhances the ability to break through extremely hard, compact soils and rock. Mining operations prefer twin tiger tips over single tiger tips when facing the most challenging ground conditions. The increased penetration comes at the cost of faster wear and a rougher finish, but the efficiency gains in tough environments often outweigh these drawbacks.

- Twin tiger tips are ideal for:

- Breaking hardpan and frost

- Excavating rocky terrain

- Tackling compacted soils

Flare Bucket Tips

Flare bucket tips stand out due to their unique flare shape, which reduces resistance in soft soils such as peat, sand, and light clay. The specialized tooth profile and mounting geometry ensure a tight grip and stability under heavy loads, minimizing vibration and premature wear. Flare tips use high-grade wear-resistant alloy steel, making them suitable for dredging and underwater excavation. However, they are not recommended for hard rock or densely compacted materials.

Tip: Flare bucket tips extend service life in soft ground conditions and improve efficiency in dredging operations.

Penetration Bucket Tips

Penetration bucket tips focus force through sharp, reinforced teeth, enabling efficient digging in dense, compacted, or frozen ground. These tips are common on rock and frost buckets, where their aggressive design breaks through tough surfaces with minimal stress on the excavator. Operators benefit from increased productivity and reduced equipment wear when using penetration tips in challenging conditions.

Abrasion-Resistant Bucket Tips

Mining Excavator Bucket Tips designed for abrasion resistance use advanced alloys such as tungsten carbide or chromium carbide overlays. Manufacturers apply these materials through welding or composite methods, creating a hardened surface layer that withstands intense abrasion and impact. Surface treatments like thermal spray or ceramic coatings further enhance resistance to wear, corrosion, and heat. These tips are essential in environments with high abrasive loads, such as handling sand, gravel, or ore.

Note: Abrasion-resistant tips extend equipment life and reduce maintenance costs, especially in harsh mining environments.

Skeleton Bucket Tips

Skeleton bucket tips feature a grid or ribbed structure that allows finer materials to pass through while retaining larger debris. Operators use these tips to sort and separate materials on-site, improving efficiency and reducing manual labor. Skeleton buckets, constructed from high-tensile, abrasion-resistant steel, support recycling and sustainable practices by facilitating material separation directly at the excavation site.

- Primary applications:

- Sifting out fines before crushing

- Sorting rocks and debris from soil

- Enhancing material handling efficiency

Ripper Bucket Tips

Ripper bucket tips concentrate machine power on a single point, increasing penetration and breakout force. These tips excel at breaking up hard soil, compacted ground, and frozen layers. Operators use ripper tips to prepare sites before excavation, saving time and reducing labor costs. The design reduces wear on machinery, prolongs equipment life, and improves safety by preventing accidents during tough digging tasks.

- Operational benefits:

- Enhanced excavation accuracy

- Lower maintenance expenses

- Effective operation in challenging conditions

V-Bucket Tips

V-bucket tips use a V-shaped design to concentrate digging force at a pointed tip. This shape allows the bucket to penetrate dense, compacted, or rocky materials with less effort, creating clean, narrow trenches. V-bucket tips are ideal for laying pipes, cables, or drainage ditches in mining projects. The design reduces strain on the excavator and increases productivity, especially in demanding environments.

Callout: Ningbo Digtech (YH) Machinery Co.,Ltd. supplies a comprehensive range of Mining Excavator Bucket Tips, including specialized designs for every mining scenario. Their products combine advanced materials and innovative engineering to deliver superior performance and durability.

How to Choose the Right Mining Excavator Bucket Tips

Assessing Mining Conditions

Selecting the optimal Mining Excavator Bucket Tips begins with a thorough assessment of the mining site. Operators must evaluate several factors to ensure the tips match the demands of the environment and the equipment. Key considerations include:

- Balancing the hardness and impact resistance of bucket teeth to prevent premature wear or breakage.

- Matching bucket teeth with compatible adaptors to avoid early wear and breakages.

- Confirming long-term supply availability of bucket teeth and adaptors to maintain productivity.

- Planning inventory and maintenance cycles with supplier support for timely replacement parts.

- Prioritizing workplace health and safety by using safer bucket teeth systems and reducing the frequency of changeouts.

Operators also need to assess material classification and density to determine the appropriate bucket size and type. Matching the bucket size with hauler or truck capacity optimizes loading efficiency. Choosing the right bucket type for the application—such as general purpose for mixed soils, heavy duty for hard materials, grading for landscaping, trenching for precise digging, or angle tilt for sloping areas—ensures the equipment performs efficiently. Operational demands and productivity goals should guide the final selection.

Tip: Failing to identify the material type and density before selection can lead to increased wear, inefficiency, and higher costs.

Considering Material Hardness

Material hardness plays a critical role in determining the most suitable bucket tip type and material. Harder, more abrasive materials require bucket tips that balance hardness and toughness to resist both wear and impact. Alloy steel, high manganese steel, and tungsten carbide are preferred for challenging mining environments due to their superior wear and impact resistance. However, excessive hardness without adequate toughness can cause brittleness and cracking, so a balanced composition is essential.

Laboratory and field tests show that bucket tip materials with alloying elements like chromium, niobium, vanadium, and boron offer improved hardness and abrasive wear resistance. For example, weld overlaid steels with higher chromium content demonstrate significantly better wear resistance. Steels that can work harden during service also show lower wear rates, which is vital when mining hard materials. Coatings and hardfacing techniques further enhance durability, especially in abrasive conditions. Softer soils may only require standard steel tips, but mining and abrasive environments demand harder, wear-resistant materials to extend tip lifespan and reduce maintenance costs.

Matching Tip Design to Project Requirements

Each mining project presents unique challenges that require specific bucket tip designs. Operators must align the tip design with the project’s terrain, soil type, climate, and operational scale. The following table summarizes common bucket types, their design features, and suitable project conditions:

| Bucket Type | Design Features & Purpose | Suitable Mining Project Conditions |

|---|---|---|

| Rock Bucket | Heavy-duty, abrasion-resistant teeth | Rocky terrain, quarrying, high-durability needs |

| High-Capacity Bucket | Larger size for bulk material movement | Large-scale mining, bulk handling |

| Swamp Bucket | Prevents sinking in soft, marshy ground | Soft, unstable soils, wetlands |

| V Bucket | V-shaped tip for breaking frozen or compacted soils | Cold climates, frozen ground |

| Ripper Bucket | Heavy-duty shanks for loosening hard surfaces | Initial ground prep on hard or compacted sites |

Operators should assess soil conditions, climate impact, project scale, and excavator compatibility. For example, frozen soils require V buckets, while soft, wet soils benefit from swamp buckets. The bucket’s size and capacity must align with the project’s scale to maintain efficiency and avoid operational issues. Power, weight, reach, and attachment compatibility of the excavator are also critical to ensure effective performance.

Note: Common mistakes include overestimating or underestimating bucket size, mismatching bucket size with excavator specifications, and ignoring the material type. These errors can lead to inefficiency, increased wear, and higher operational costs.

Balancing Durability and Cost

Mining Excavator Bucket Tips made from high-quality materials such as premium steels often carry a higher initial cost. However, these tips provide better resistance to wear and impact, reducing the frequency of replacements and maintenance. Advanced manufacturing techniques like forging, heat treatment, and precision machining enhance durability and performance, though they add to production costs.

| Material/Process Type | Advantages | Disadvantages/Cost Implications |

|---|---|---|

| High Manganese Alloy Steel | Improved toughness, hardness, wear resistance | Higher cost due to alloying elements |

| Ultra-High Manganese Alloy | Excellent strength, toughness, superior hardening | Increased cost from higher alloy content |

| Casting Process | Cost-effective for large quantities, complex shapes | Potential internal defects |

| Forging Process | Higher density, fewer defects, better properties | More expensive, complex shapes harder to produce |

| Machining Process | Improved accuracy and surface quality | Adds cost due to time and material waste |

Despite the higher upfront investment, durable bucket tips minimize downtime and repair expenses, leading to long-term cost savings. Operators must weigh the benefits of extended service life and reduced maintenance against the initial purchase price. In most mining operations, the use of more durable, expensive bucket tips proves economically justified due to the reduction in replacement frequency and improved productivity.

Selecting the right Mining Excavator Bucket Tips ensures efficient, safe, and cost-effective mining operations.

- Using abrasion-resistant steel can extend equipment life by up to 30%.

- Regular inspections and prompt replacement of worn tips maintain productivity and reduce downtime.

| Bucket Tip Type | Unique Benefit |

|---|---|

| Rock | Penetrates hard, rocky terrain |

| V Bucket | Excels in compacted soils |

FAQ

What is the average lifespan of a mining excavator bucket tip?

Most bucket tips last between 12 and 24 months. Lifespan depends on material hardness, mining conditions, and maintenance frequency.

How often should operators inspect bucket tips for wear?

Operators should inspect bucket tips weekly. Early detection of cracks or excessive wear prevents equipment failure and reduces downtime.

Can operators replace bucket tips without special tools?

Most modern bucket tips use pin-and-lock systems. Operators can replace them with basic hand tools, following manufacturer safety guidelines.

Post time: Jul-24-2025