Mine-grade cutting edge bolts play a vital role in mining equipment, including heavy-duty track connection bolts and heavy-duty hexagonal bolt assemblies. Companies source these bolts globally, as the construction bolt market is valued at USD 46.43 billion in 2024 and set to reach USD 48.76 billion in 2025. Motor grader blade bolts must meet strict performance standards, and Multiport Service Terminal Box integration helps streamline operations.

Key Takeaways

- Choose high-quality bolts made from strong alloy steel that meet strict certifications like ISO 9001 and ASTM to ensure durability and safety in mining operations.

- Verify supplier credentials, reputation, and supply chain reliability to avoid delays and guarantee consistent delivery of compliant bolts.

- Manage costs by considering total ownership expenses, negotiating clear contracts, and optimizing inventory with modern tools to keep mining equipment running smoothly and affordably.

Key Factors in Sourcing Mine-grade Cutting Edge Bolts

Quality and Performance Requirements

Mining operations demand bolts that can withstand extreme conditions. Companies look for bolts with high tensile and yield strength, made from advanced alloy steel. These bolts must fit perfectly with original equipment and deliver consistent performance. The following table highlights the most common benchmarks for mine-grade cutting edge bolts:

| Benchmark Aspect | Details |

|---|---|

| Tensile Strength | Minimum 800 MPa (ISO 898-1 Class 8.8); mining bolts often exceed 1,600 MPa |

| Yield Strength | Minimum 640 MPa (ISO 898-1 Class 8.8) |

| Material | High-grade alloy steel for wear, corrosion, and temperature resistance |

| Engineering Precision | Designed for perfect fit and compatibility with OEM specifications |

| Certifications | CE, ISO9001 |

| Manufacturer Standards | Caterpillar and other OEM-specific standards |

| Performance Benefits | Durability, load distribution, track stability, safety, reduced downtime and maintenance |

Ningbo Digtech (YH) Machinery Co.,Ltd. manufactures bolts that meet or exceed these benchmarks. Their products help mining companies reduce downtime and improve equipment safety. High-quality bolts also lower maintenance costs and extend the life of mining machinery.

Compliance with Mining Industry Standards

Strict standards govern the manufacturing and testing of mine-grade cutting edge bolts. Companies must ensure that every bolt meets international requirements for strength, durability, and safety. The most recognized certifications include:

- ISO 9001 certification, which shows strong quality management.

- ASTM certifications, which confirm that bolts meet quality and safety standards.

Tip: Always request documentation for certifications like ISO 9001 and ASTM when evaluating suppliers. This step helps ensure that bolts will perform reliably in demanding mining environments.

Ningbo Digtech (YH) Machinery Co.,Ltd. maintains these certifications, giving buyers confidence in product compliance and reliability.

Cost-effectiveness and Value Assessment

Mining companies face many challenges when sourcing bolts globally. They must balance quality, compliance, and cost. Common challenges include:

- Ensuring product quality and compliance without direct oversight.

- Communication barriers due to language and cultural differences.

- Complex logistics, including shipping, customs, and regulations.

- Finding reliable suppliers in a competitive market.

- Rising raw material costs and supply chain disruptions.

- The need for sustainable manufacturing and corrosion-resistant materials.

Global supply chain disruptions, such as geopolitical tensions and trade restrictions, can reduce the availability of raw materials. This situation leads to production delays and price volatility. For example, steel and alloy prices often fluctuate, making it hard to predict costs. Shipping costs may rise due to port congestion or labor strikes, further impacting budgets.

Ningbo Digtech (YH) Machinery Co.,Ltd. addresses these challenges by investing in advanced manufacturing and logistics. Their strong supply chain helps stabilize prices and ensures timely delivery. By choosing a supplier with proven reliability, mining companies can minimize risk and maximize value in 2025.

Understanding Mine-grade Cutting Edge Bolts

Types and Applications in Mining

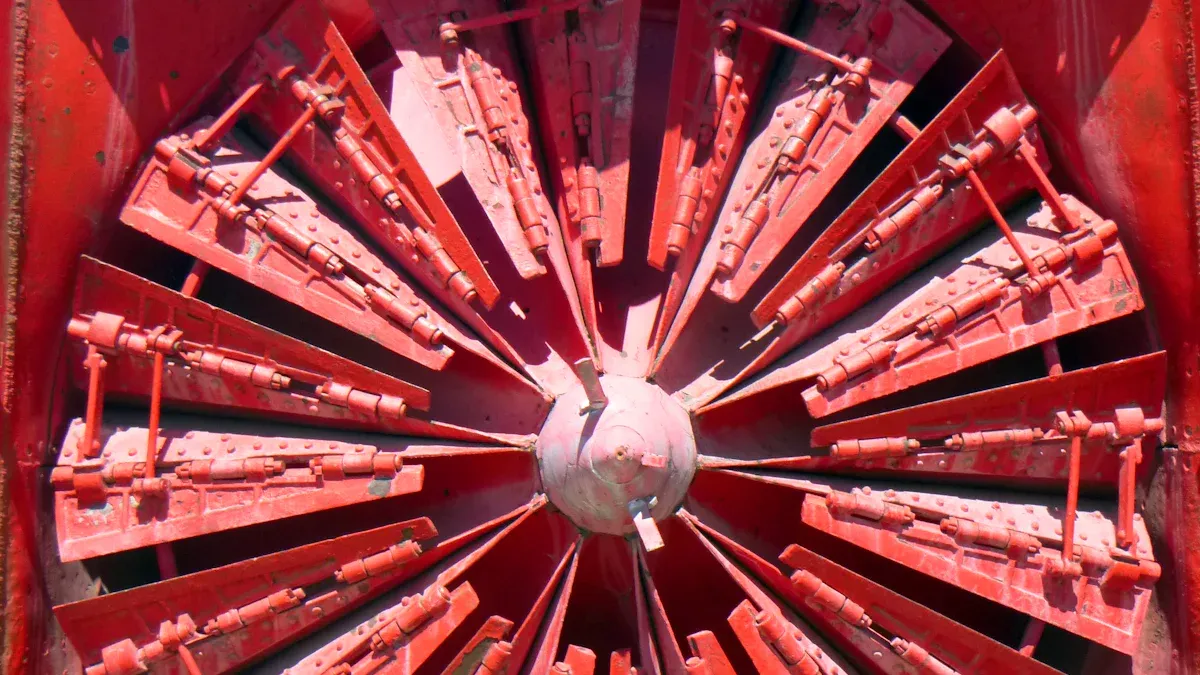

Mining operations rely on several types of cutting edge bolts to keep equipment running safely and efficiently. These bolts serve as essential fasteners and ground engaging tools in machines such as excavators, graders, and dozers.

- Cutting edge bolts secure the replaceable edges on blades and buckets.

- Plow bolts attach cutting edges to grader blades and dozer blades, providing a flush fit that prevents snagging.

- Hex bolts offer versatility for various mining attachments.

- Segment bolts hold together segmented edges on larger buckets.

- Bucket tooth pins fasten replaceable teeth to loader and excavator buckets.

Each bolt type supports the integrity and performance of mining equipment. These bolts withstand harsh conditions, including constant impact with rock and soil. Proper selection and installation help maintain the functionality of wear parts and reduce the risk of equipment failure.

Importance of Specifications and Material Grades

Material grade and specifications determine the lifespan and maintenance needs of cutting edge bolts. Harder steel, such as Hardox 500, provides consistent hardness throughout the bolt. This feature extends the wear life by two to three times compared to standard OEM steel, reducing the need for frequent replacements.

| Feature | Dozer Cutting Edge | Grader Blade |

|---|---|---|

| Primary Use | Heavy material pushing and earthmoving | Surface grading, shaping, and smoothing |

| Thickness | Up to 2.5 inches or more | 1 to 1.5 inches |

| Material Hardness | High abrasion resistance, impact-tough | Moderate wear resistance |

| Blade Mounting Style | Single edge or double beveled | Bolted edge sections |

| Application Speed | Low speed with high torque | Higher speed, lower torque |

| Versatility | Bulk movement, rough grading | Fine grading, finishing |

Note: Using new bolts and nuts, cleaning all surfaces, and tightening bolts to the correct torque can further extend the lifespan of cutting edges and bolts. Proper maintenance reduces downtime and keeps mining operations productive.

Evaluating Global Suppliers for Mine-grade Cutting Edge Bolts

Verifying Certifications and Industry Credentials

Mining companies must check that suppliers hold valid certifications before making a purchase. Certifications such as ISO 17025, ANSI Accreditation, and EU Notified Bodies listings confirm that a supplier meets strict industry standards. These credentials show that the supplier’s products have passed rigorous testing and comply with global regulations. Ningbo Digtech (YH) Machinery Co.,Ltd. maintains these certifications, which gives buyers confidence in the quality and safety of their bolts. Companies should always request up-to-date documentation and verify credentials through official channels.

Assessing Supplier Reputation and Experience

A supplier’s reputation and experience play a key role in the selection process. Buyers often look for the following indicators:

- Customer reviews and testimonials from mining companies

- Case studies that highlight successful projects

- Years of service in the mining and heavy machinery sectors

- Ability to deliver custom solutions for unique operational needs

- Products that perform well in harsh mining environments

Ningbo Digtech (YH) Machinery Co.,Ltd. has built a strong reputation by delivering reliable products and tailored solutions. Their long-standing presence in the industry demonstrates expertise and trustworthiness.

Supply Chain Strength and Reliability

A robust supply chain ensures that bolts arrive on time and meet project deadlines. Leading suppliers maintain global logistics networks, manage inventory efficiently, and partner with trusted manufacturers. They also use strict quality assurance processes, including tensile strength and corrosion resistance tests. Companies like Ningbo Digtech (YH) Machinery Co.,Ltd. invest in these systems to guarantee consistent delivery and product reliability. Reliable supply chains help mining operations avoid costly delays and keep equipment running smoothly.

Ensuring Product Quality and Compliance

Quality Control and Testing Protocols

Mining companies demand strict quality control for cutting edge bolts. Leading suppliers use advanced testing protocols to guarantee each bolt meets industry standards. They follow ASTM guidelines to check hardness, strength, and durability. The table below shows common ASTM standards used before shipment:

| ASTM Standard | Testing Focus | Relevance to Mine-Grade Cutting Edge Bolts |

|---|---|---|

| ASTM E92 | Hardness testing (Vickers, Knoop) | Ensures bolt hardness meets specifications for durability in mining environments |

| ASTM E384 | Microhardness testing | Verifies surface hardness critical for wear resistance |

| ASTM A956 | Hardness testing for steel nuts and bolts | Confirms mechanical properties for bolts under stress |

| ASTM E8/E8M | Tensile testing | Measures tensile strength and proof load to ensure bolts withstand operational loads |

| ASTM E1820 | Fracture toughness testing | Assesses resistance to crack propagation, critical for safety in harsh mining conditions |

| ASTM A194 | Specifications for carbon and alloy steel nuts for high-pressure/high-temperature service | Provides mechanical and chemical property requirements ensuring bolt assemblies perform reliably in severe mining environments |

These tests help suppliers deliver bolts that perform well in tough mining conditions.

Meeting International Mining Regulations

Mining operations must follow strict international regulations. Suppliers design bolts to meet ISO, ASTM, and regional mining standards. They use certified materials and document every step of production. Regular audits and inspections confirm compliance. Companies that meet these regulations reduce the risk of equipment failure and improve worker safety. Reliable suppliers stay updated on changing rules to keep their products compliant.

Documentation and Traceability

Suppliers maintain detailed records for every bolt. They track materials, manufacturing steps, inspections, and test results. This process creates a clear trail from raw material to finished product.

- Comprehensive records of materials and processes support traceability.

- Inspection and testing logs help identify and resolve quality issues quickly.

- ISO 9001 certified quality management systems ensure continuous improvement.

- Consistent documentation guarantees that bolts meet strict quality standards.

These practices give mining companies confidence in the bolts they use and help resolve any issues fast.

Managing Logistics, Shipping, and Multiport Service Terminal Box Integration

Navigating Import and Export Regulations

Mining companies face strict import and export regulations when sourcing mine-grade cutting edge bolts. Each country sets its own rules for documentation, tariffs, and customs clearance. Companies must prepare accurate shipping documents and follow all legal requirements. They often work with customs brokers to avoid delays. The Multiport Service Terminal Box helps streamline documentation by centralizing shipment data. This solution reduces errors and speeds up customs processing.

Shipping Methods and Lead Time Optimization

Selecting the right shipping method impacts both cost and delivery time. Air freight offers speed but costs more. Ocean freight provides savings for large shipments but takes longer. Companies track shipments using digital platforms connected to the Multiport Service Terminal Box. This system gives real-time updates and helps teams plan for arrivals. By monitoring lead times, companies can adjust orders and avoid equipment downtime.

Tip: Use the Multiport Service Terminal Box to coordinate shipments from multiple suppliers. This approach improves efficiency and reduces the risk of lost or delayed cargo.

Integrating Multiport Service Terminal Box Solutions

The Multiport Service Terminal Box acts as a central hub for logistics management. It connects suppliers, shippers, and mining sites through one platform. Teams use it to track inventory, manage documents, and communicate with partners. The system supports integration with other supply chain tools. Companies gain better visibility and control over shipments. The Multiport Service Terminal Box also helps with compliance by storing records and audit trails. Mining operations benefit from fewer delays and improved coordination.

Cost Management Strategies for Global Sourcing

Comparing Pricing Models and Total Cost of Ownership

Mining companies often compare different pricing models before making a purchase. Some suppliers offer fixed pricing, while others use variable rates based on market conditions. Companies must look beyond the initial price. They should consider the total cost of ownership (TCO), which includes shipping, customs fees, storage, and maintenance. A simple table can help teams compare options:

| Pricing Model | Pros | Cons |

|---|---|---|

| Fixed Price | Predictable budgeting | May miss market savings |

| Variable Price | Potential for lower costs | Harder to forecast expenses |

| TCO Approach | Full cost visibility | Requires more analysis |

By focusing on TCO, companies can make better decisions and avoid hidden expenses.

Negotiating Terms with Global Suppliers

Strong negotiation skills help mining companies secure better deals. Teams should discuss payment terms, delivery schedules, and warranty coverage. Clear contracts protect both sides and set expectations. Many buyers request volume discounts or flexible payment plans. They also ask for penalties if suppliers miss deadlines. Open communication builds trust and leads to long-term partnerships.

Tip: Always document agreements in writing to prevent misunderstandings.

Optimizing Order Quantities and Inventory

Efficient inventory management reduces costs and prevents supply disruptions. Companies use predictive analytics to forecast demand and spot potential delays. They work closely with suppliers, sharing data and planning together. This collaboration uses tools like Vendor Managed Inventory (VMI) and Collaborative Planning, Forecasting, and Replenishment (CPFR). IoT technology gives real-time updates on stock levels and shipments. Industry leaders such as Toyota and Apple use these methods to keep operations smooth and costs low.

- Predictive analytics improves demand forecasting.

- Supplier collaboration ensures timely replenishment.

- VMI and CPFR streamline inventory management.

- IoT integration provides real-time visibility.

These strategies help mining companies maintain the right stock levels and avoid costly interruptions.

Procurement professionals can follow these steps for effective sourcing in 2025:

- Secure reliable suppliers of high-strength materials.

- Ensure compliance with updated quality standards.

- Use advanced manufacturing and robust quality assurance.

- Negotiate long-term contracts for supply stability.

| Aspect | Key Takeaways |

|---|---|

| Quality Assurance | Choose certified distributors and require rigorous inspections to reduce downtime. |

| Compliance | Monitor regulations and maintain high policy adherence. |

| Cost Savings | Optimize logistics and use group purchasing for lower costs. |

| Material & Performance | Select bolts with strong alloy steel and proven durability. |

Sourcing teams who prioritize these strategies will ensure quality, compliance, and cost savings in mining operations.

FAQ

What certifications should mine-grade cutting edge bolts have?

Mining companies should look for ISO 9001 and ASTM certifications. These show the bolts meet strict quality and safety standards.

How can buyers ensure bolt traceability?

Buyers should request full documentation. Suppliers must provide records for materials, manufacturing, and testing. This ensures every bolt can be traced from start to finish.

Why does material grade matter for mining bolts?

Material grade affects bolt strength and lifespan. High-grade alloy steel resists wear and corrosion. This helps mining equipment last longer and reduces maintenance costs.

Tip: Always ask suppliers for material test reports before placing an order.

Post time: Jul-10-2025