High-strength track bolt and nut assemblies play a pivotal role in maintaining the stability and performance of crawler undercarriages. In Chile’s copper mines, track bolt and nut systems, as well as segment bolt and nut combinations, endure extreme stress, often requiring replacements every 800-1,200 hours. Additionally, plow bolt and nut solutions are essential for various heavy machinery applications. The European Machinery Directive 2023 mandates ultrasonic testing to enhance safety, highlighting the critical need for reliable fasteners in demanding operations.

Key Takeaways

- Strong track bolts and nuts are important for crawler undercarriages. They keep tracks in place, helping machines work well in tough areas.

- Checking track bolts and nuts often can spot damage early. Fixing problems early avoids expensive repairs and keeps equipment working better.

- Using strong materials for bolts and nuts lowers repair costs. Tough parts last longer, so you replace them less often, saving money and time.

Understanding Crawler Undercarriages

Overview of Crawler Undercarriages

Crawler undercarriages form the foundation of heavy machinery, enabling efficient movement across rugged terrains. These systems consist of tracks, rollers, and other components designed to distribute weight evenly and maintain stability. Recent advancements in the crawler track undercarriage market highlight the adoption of lightweight materials like high-strength steel and advanced polymers. These innovations improve durability and fuel efficiency, allowing machinery to perform effectively in challenging environments. Additionally, the integration of IoT sensors for real-time monitoring reflects a shift toward smarter, more efficient machinery. This trend is particularly evident in developing regions such as Asia-Pacific, where infrastructure investments drive demand for reliable equipment.

Key Components and Their Functions

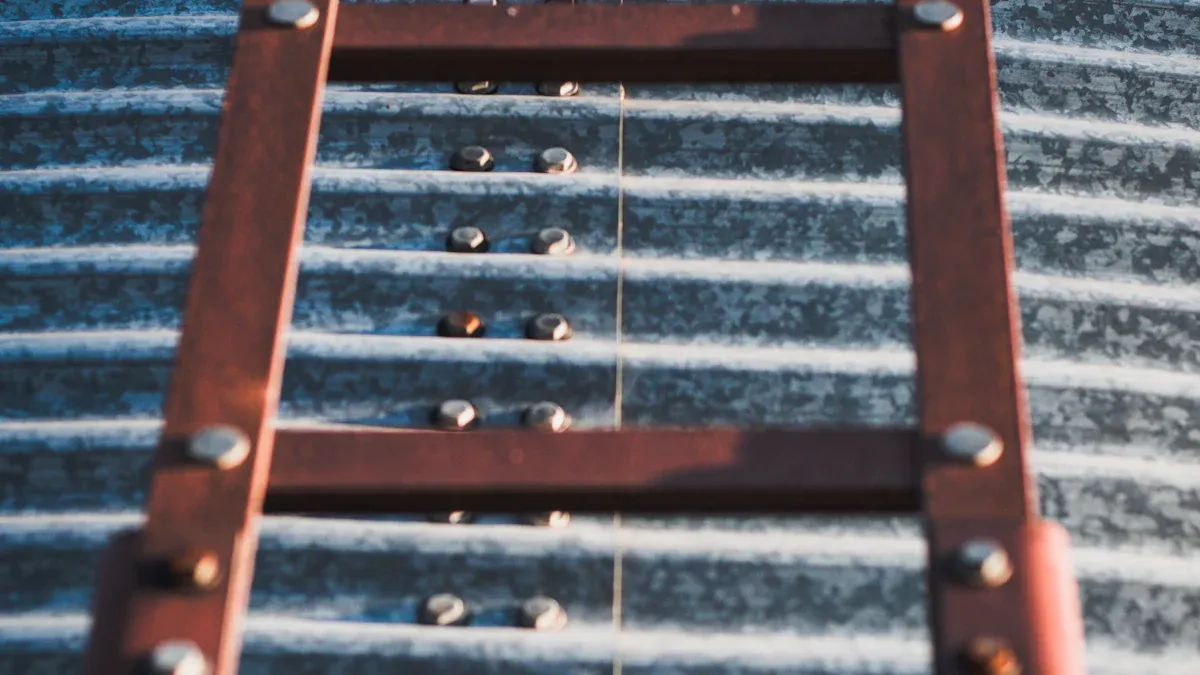

Crawler undercarriages rely on several critical components to ensure optimal performance:

- Tracks: These provide traction and support, enabling the machinery to traverse uneven surfaces.

- Rollers and Idlers: These guide and support the tracks, ensuring smooth operation and proper alignment.

- Track Bolt and Nut Assemblies: These secure the tracks to the undercarriage, maintaining structural integrity under heavy loads.

- Drive Sprockets: These transfer power from the engine to the tracks, propelling the machinery forward.

Customization trends in the industry emphasize tailored solutions to meet specific operational needs. For example, special environmental adaptability testing ensures components perform reliably in extreme temperatures or corrosive conditions. Inspection and evaluation processes, such as wear trace analysis and sealing performance verification, further enhance the durability and efficiency of these systems. By adhering to industry standards like ISO 6014, manufacturers ensure that crawler undercarriages meet rigorous performance benchmarks.

The Role of Track Bolt and Nut in Crawler Undercarriages

Ensuring Stability and Structural Integrity

Track bolts and nuts serve as the backbone of crawler undercarriages. These components secure the tracks to the undercarriage frame, preventing displacement during operation. Heavy machinery often operates in environments where uneven terrain and high-impact forces challenge structural stability. Without reliable fasteners, the tracks could loosen or detach, compromising the machine’s ability to function safely and efficiently.

Manufacturers design track bolts and nuts to withstand extreme stress and vibrations. High-strength materials, such as alloy steel, ensure these fasteners maintain their integrity under heavy loads. Precision engineering further enhances their performance, allowing them to resist wear and deformation over time.

Tip: Regular inspection of track bolts and nuts can help identify early signs of wear or damage, ensuring timely replacements and preventing costly breakdowns.

Contribution to Load Distribution and Alignment

Track bolts and nuts play a crucial role in distributing weight evenly across the undercarriage. Proper load distribution minimizes stress on individual components, extending their lifespan and reducing the risk of mechanical failure. By securing the tracks firmly, these fasteners ensure the machinery maintains optimal alignment during operation.

Misaligned tracks can lead to uneven wear, reduced efficiency, and increased fuel consumption. Track bolts and nuts prevent such issues by keeping the tracks in their intended position. This alignment is particularly important in applications like mining and construction, where machinery must navigate challenging terrains while carrying heavy loads.

A well-maintained track bolt and nut system contributes to smoother operation and improved performance. Operators can rely on their machinery to handle demanding tasks without interruptions, enhancing productivity and safety on the job site.

Importance of High-Strength Materials in Track Bolts and Nuts

Resistance to Heavy Loads and Stress

High-strength materials in track bolts and nuts are essential for handling the immense loads and stresses encountered in heavy machinery operations. These fasteners must endure constant pressure from uneven terrains, vibrations, and the weight of the equipment itself. Laboratory tests confirm their ability to resist such forces through rigorous evaluations.

| Testing Type | Description |

|---|---|

| Mechanical Testing | Includes proof load testing, tensile testing, and hardness testing (Rockwell, Brinell, etc.) |

| Metallurgical Testing | Involves microhardness testing, microstructural assessments, and metallurgical failure investigations |

| Chemical Analysis | Comprises ICP/OES and Spark OES analysis to evaluate material composition and properties |

These tests ensure that track bolts and nuts meet industry standards for strength and reliability. Regular testing of fasteners and raw materials guarantees their suitability for demanding environments. Bolt testing also verifies that these components can withstand their designated load and function effectively under operational stresses.

Durability in Harsh Environments

Track bolts and nuts must perform reliably in extreme conditions, including high temperatures, corrosive environments, and constant exposure to external forces. Field tests and environmental assessments demonstrate their durability in such settings.

- Prevailing torque testing evaluates how effectively fasteners resist loosening due to vibrations and external forces.

- This testing is critical in industries like nuclear, aerospace, and marine, where fastener integrity prevents catastrophic failures.

- Results from these tests ensure that track bolts and nuts meet minimum standards for their intended applications, reducing defects and enhancing durability.

By resisting wear and loosening, high-strength materials extend the lifespan of track bolt and nut assemblies. This durability minimizes maintenance needs and ensures machinery operates safely and efficiently in challenging environments.

Benefits of High-Strength Track Bolts and Nuts

Enhanced Safety and Reliability

High-strength track bolts and nuts significantly enhance the safety and reliability of crawler undercarriages. These components ensure that tracks remain securely fastened, even under extreme operational conditions. By preventing track displacement or detachment, they reduce the risk of accidents and equipment failure.

The use of advanced materials, such as alloy steel, provides exceptional resistance to stress and vibration. This durability ensures that the fasteners maintain their integrity over time, even in high-impact environments like construction sites or mining operations. Operators can trust their machinery to perform consistently, knowing that the track bolt and nut assemblies are designed to handle demanding tasks.

Note: Regular inspections and torque checks further improve safety by identifying potential issues before they escalate into critical failures.

Longer Lifespan of Undercarriage Components

High-strength track bolts and nuts contribute to the extended lifespan of undercarriage components. By securing the tracks firmly, they minimize unnecessary movement and wear on adjacent parts, such as rollers, idlers, and sprockets. This stability reduces the strain on individual components, allowing them to function efficiently for longer periods.

Proper load distribution, facilitated by these fasteners, also plays a key role in preserving the undercarriage. Uneven weight distribution can lead to premature wear and tear, but high-quality bolts and nuts ensure that the load is evenly spread across the system. This balance not only enhances performance but also delays the need for costly replacements.

Manufacturers often recommend using fasteners that meet industry standards to maximize the durability of the entire undercarriage assembly. Investing in high-strength components ultimately saves time and resources by reducing the frequency of repairs.

Lower Maintenance Costs and Downtime

Using high-strength track bolts and nuts can significantly lower maintenance costs and minimize downtime. These fasteners are engineered to withstand harsh conditions, reducing the likelihood of unexpected failures. As a result, operators spend less time addressing mechanical issues and more time focusing on productive tasks.

The durability of these components also translates to fewer replacements, which lowers overall maintenance expenses. For industries like mining and construction, where equipment downtime can lead to substantial financial losses, this reliability is invaluable.

Tip: Implementing a proactive maintenance schedule that includes regular inspections of track bolts and nuts can further reduce downtime and ensure optimal performance.

By choosing high-strength fasteners, businesses can achieve a balance between operational efficiency and cost-effectiveness. This investment not only enhances the performance of crawler undercarriages but also supports long-term profitability.

Selecting and Maintaining Track Bolts and Nuts

Factors to Consider When Choosing High-Strength Bolts and Nuts

Selecting the right high-strength bolts and nuts is crucial for ensuring the performance and safety of crawler undercarriages. Several technical criteria and industry standards guide this process:

- Material Selection: Opt for materials like steel, stainless steel, or alloy steel to achieve high tensile strength and durability.

- Coating Options: Use coatings such as zinc plating or galvanizing to enhance corrosion resistance, especially in harsh environments.

- Size and Type: Ensure the fastener type and size align with the application, referencing ASTM fastener standards for accuracy.

- Key Performance Factors: Consider bolt diameter, pretension degree, and tensile strength, as these significantly impact shear performance and load capacity.

- Environmental Conditions: Evaluate factors like temperature, pressure, and corrosiveness to ensure the fasteners can withstand operational challenges.

Proper installation techniques also play a vital role in maximizing the effectiveness of track bolt and nut assemblies. For example, using double nuts or spring tightening can help control pretension loss, improving long-term reliability.

Maintenance Tips for Optimal Performance

Effective maintenance practices are essential for optimizing the performance and lifespan of track bolts and nuts. Regular inspections and proactive measures can prevent costly failures. Key maintenance tips include:

- Schedule Regular Inspections: Examine fasteners for signs of wear, corrosion, or loosening.

- Keep Detailed Records: Maintain logs of maintenance activities to track performance trends and identify recurring issues.

- Empower Operators: Train operators to recognize early warning signs of fastener failure, such as unusual vibrations or misalignment.

- Leverage Technology: Use fleet maintenance software or CMMS analytics to monitor fastener performance and adjust maintenance schedules accordingly.

- Invest in Smart Tools: Utilize torque wrenches and other precision tools to ensure proper tightening during installation and maintenance.

Preventive maintenance strategies, such as Asset Performance Management (APM), emphasize data collection and predictive analysis. These approaches help identify inefficiencies and optimize maintenance schedules, ensuring crawler undercarriages operate safely and efficiently.

Tip: Automatic undercarriage washers can reduce maintenance time and improve productivity by eliminating manual cleaning tasks.

High-strength track bolts and nuts are vital for ensuring the safety, durability, and efficiency of crawler undercarriages. Their role in maintaining structural integrity and reducing maintenance costs cannot be overstated.

Investing in premium-quality fasteners enhances equipment performance and minimizes downtime, offering long-term cost savings and operational reliability. Choose wisely for lasting results.

FAQ

What makes high-strength track bolts and nuts different from standard fasteners?

High-strength track bolts and nuts use advanced materials like alloy steel. They resist heavy loads, vibrations, and environmental stress, ensuring durability and reliability in demanding applications.

How often should track bolts and nuts be inspected?

Inspect track bolts and nuts every 500-1,000 operational hours. Regular checks help identify wear, corrosion, or loosening, preventing unexpected failures and costly downtime.

Can high-strength bolts and nuts reduce maintenance costs?

Yes, their durability minimizes replacements and repairs. This reliability reduces maintenance expenses and operational interruptions, especially in industries like mining and construction.

Post time: Apr-27-2025