High-tensile track bolt and nut assemblies ensure construction machinery operates safely under extreme stress. Their superior strength and durability make them essential for securing tracks and components. Industry applications, such as earthquake-resistant structures and railway bridges, highlight their reliability in demanding environments. Performance metrics confirm reduced failures when replacing standard bolts with high-tensile track bolt and nut solutions, ensuring optimal machinery operation. Additionally, segment bolt and nut and plow bolt and nut options provide versatile solutions for various heavy-duty applications, further enhancing equipment performance and safety.

Key Takeaways

- Strong track bolts are tough and long-lasting, keeping machines safe under heavy use.

- Checking bolts and nuts often helps stop breakdowns and keeps workers safe by spotting problems early.

- Tightening bolts with the right force is key to keeping them strong and stopping them from coming loose.

Key Features of Track Bolt and Nut

High-Strength Material Composition

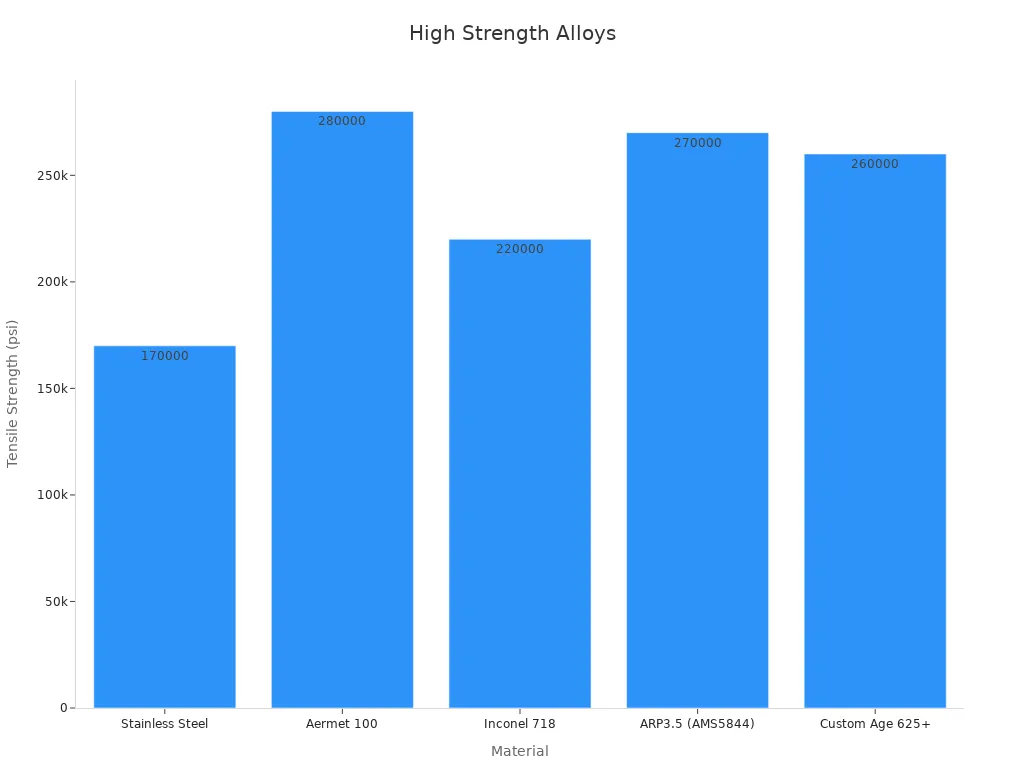

Track bolt and nut assemblies are crafted from high-strength alloys to withstand extreme stress. These materials ensure exceptional tensile strength, making them suitable for demanding construction environments. The table below highlights the tensile strength of various high-strength alloys used in manufacturing:

| Material | Typical Tensile Strength (psi) | Applications |

|---|---|---|

| Stainless Steel | 170,000 | Automotive and marine applications |

| 8740 Chrome Moly | 180,000 – 210,000 | Moderate strength for racing applications |

| ARP2000 | 215,000 – 220,000 | Short track and drag racing |

| L19 | 230,000 – 260,000 | Short track and drag racing |

| Aermet 100 | 280,000 | Extreme environments like top fuel and funny car |

| Inconel 718 | 220,000 | High temperature and lower temperature applications |

| ARP3.5 (AMS5844) | 270,000 | Aerospace applications |

| Custom Age 625+ | 260,000 | High strength, super-alloy applications |

These materials provide the durability and reliability required for securing critical components in construction machinery.

Resistance to Fatigue and Corrosion

Track bolt and nut assemblies resist fatigue and corrosion, ensuring long-term performance. Laboratory tests, such as ASTM E606, validate their ability to endure cyclic loads without failure. Key findings include:

- High-strength steel bolts excel in structural applications.

- Fatigue-related failures are minimized under cyclic loading.

- Case studies demonstrate effective prevention of fatigue-induced damage.

Corrosion resistance further enhances their lifespan, even in harsh environments. This dual resistance ensures machinery operates safely and efficiently.

Precision Engineering for Secure Fastening

Precision engineering ensures track bolt and nut assemblies provide secure fastening. Each component undergoes meticulous design and manufacturing processes to achieve exact specifications. This precision minimizes loosening under vibration and heavy loads, enhancing the stability of construction machinery. Ningbo Digtech (YH) Machinery Co., Ltd. employs advanced engineering techniques to deliver reliable solutions tailored to industry needs.

Safety Benefits of High-Tensile Track Bolts

Enhanced Stability and Load-Bearing Capacity

High-tensile track bolts significantly improve the stability of construction machinery. Their superior strength ensures that tracks and components remain securely fastened, even under heavy loads and extreme conditions. By enhancing the load-bearing capacity, these bolts reduce the risk of structural deformation and equipment instability.

Several technical parameters influence the load-bearing capacity of high-tensile bolts. The table below outlines key factors and their effects on stability:

| Parameter | Effect on Load-Bearing Capacity |

|---|---|

| Length of Anchor Rod | Increased length leads to a larger compressive stress zone, enhancing the effective bearing structure. |

| Diameter of Anchor Rod | Larger diameters improve the composite bearing compressive stress zone, contributing to overall stability. |

| Bolt Spacing | Variations in spacing affect load distribution and stability of the anchorage structure. |

These factors demonstrate how precision in bolt design and installation contributes to the overall stability of construction machinery. Ningbo Digtech (YH) Machinery Co., Ltd. ensures that its track bolt and nut assemblies meet stringent specifications to deliver optimal performance in demanding environments.

Prevention of Equipment Failures and Accidents

Equipment failures often result from inadequate fastening solutions. High-tensile track bolts mitigate this risk by providing unmatched durability and resistance to stress. Their ability to withstand vibrations and dynamic loads prevents loosening and ensures consistent performance.

Tip: Regularly inspect track bolt and nut assemblies to identify signs of wear or damage. Early detection can prevent catastrophic failures and enhance workplace safety.

By minimizing the likelihood of bolt-related failures, these components play a crucial role in accident prevention. Operators can rely on machinery equipped with high-tensile bolts to perform safely and efficiently, even in high-pressure scenarios.

Prolonged Machinery Lifespan and Reduced Downtime

The durability of high-tensile track bolts extends the operational lifespan of construction machinery. Their resistance to fatigue and corrosion ensures long-term reliability, reducing the need for frequent replacements. This longevity translates to lower maintenance costs and fewer interruptions in operations.

Reduced downtime benefits construction projects by maintaining productivity and adhering to tight schedules. Machinery equipped with robust track bolt and nut assemblies operates consistently, allowing operators to focus on achieving project goals without concerns about equipment reliability. Ningbo Digtech (YH) Machinery Co., Ltd. provides solutions designed to maximize machinery lifespan and minimize operational disruptions.

Applications of Track Bolt and Nut in Construction Machinery

Securing Tracks on Excavators and Bulldozers

Track bolt and nut assemblies play a vital role in securing tracks on excavators and bulldozers. These machines operate in rugged environments, where stability and reliability are critical. The bolts ensure that tracks remain firmly attached to the undercarriage, even during heavy-duty operations. This secure fastening prevents track slippage, which could lead to operational delays or safety hazards.

The high-tensile strength of these bolts allows them to withstand the immense forces generated by the movement of excavators and bulldozers. Their resistance to vibration and dynamic loads ensures consistent performance, even in challenging conditions. By maintaining track integrity, these bolts contribute to the overall efficiency and safety of construction projects.

Use in Cranes, Loaders, and Heavy-Duty Equipment

Cranes, loaders, and other heavy-duty equipment rely on track bolt and nut assemblies for optimal performance. These machines often handle substantial loads, making secure fastening essential. The bolts provide the necessary strength to support the weight and stress associated with lifting and moving heavy materials.

In cranes, the bolts ensure the stability of the base structure, reducing the risk of tipping or structural failure. Loaders benefit from the bolts’ ability to maintain track alignment, which is crucial for smooth operation. The versatility of these assemblies makes them suitable for various heavy-duty applications, enhancing the reliability and safety of construction machinery.

Compatibility with Various Construction Machinery

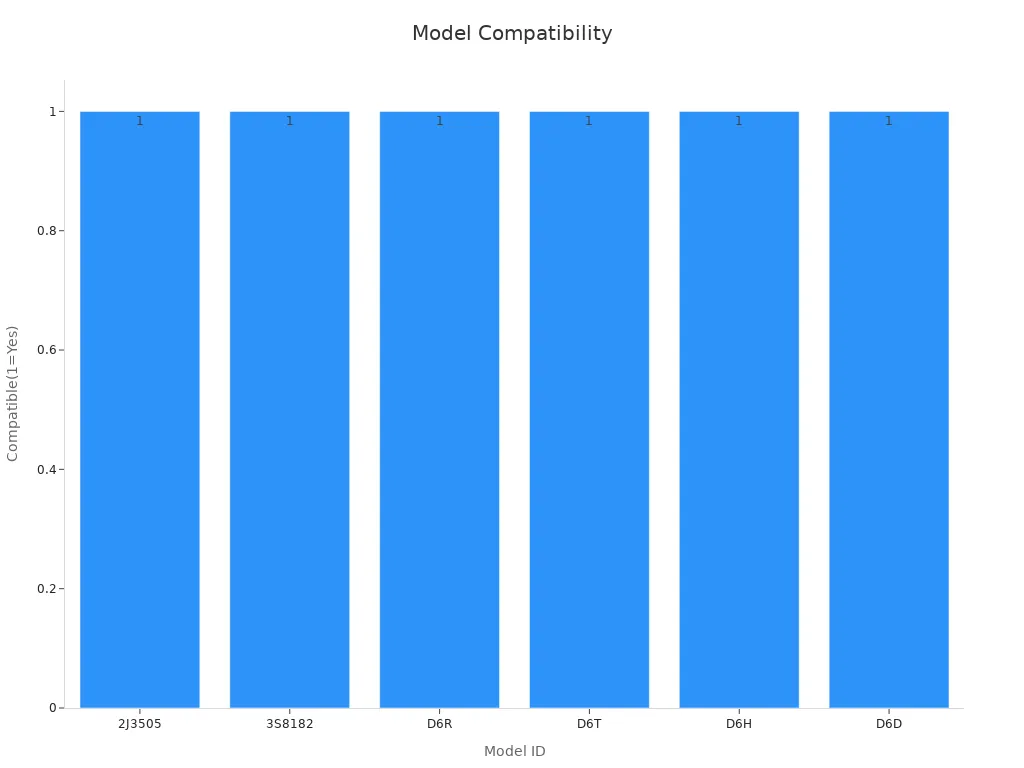

Track bolt and nut assemblies are designed to be compatible with a wide range of construction machinery models. This versatility simplifies maintenance and replacement processes, as operators can use the same type of bolts across different machines. Compatibility testing across various models validates their adaptability, ensuring seamless integration into diverse equipment.

The table below highlights the compatibility of track bolt and nut assemblies with popular construction machinery models:

| Model | Compatibility |

|---|---|

| 2J3505 | Yes |

| 3S8182 | Yes |

| D6R | Yes |

| D6T | Yes |

| D6H | Yes |

| D6D | Yes |

This compatibility ensures that operators can rely on these bolts for consistent performance across different machines. Ningbo Digtech (YH) Machinery Co., Ltd. offers track bolt and nut solutions that meet the requirements of various construction machinery, providing a reliable and efficient fastening system.

Maintenance Tips for Track Bolt and Nut

Regular Inspection for Wear and Damage

Regular inspections are essential for maintaining the integrity of track bolts and nuts. These inspections help identify early signs of wear or damage, preventing potential failures. Ultrasonic testing, a non-destructive method, has proven effective in assessing bolt conditions. This technique detects early failures and evaluates bolt integrity without causing damage. For example, phased array testing provides clear images of a bolt’s interior, making on-site interpretation easier.

| Diagnostic Procedure | Description |

|---|---|

| Ultrasonic Testing | Non-destructive method to check the condition of bolts without causing damage. |

| Conventional Ultrasonic Testing | Provides A-scan (amplitude-time plot) for expert interpretation. |

| Phased Array Testing | Offers an image of the bolt’s interior, easier to interpret on-site. |

| Simulation of Defect | A 2 mm cut was simulated to test detection capabilities, showing clear indications in the images. |

| Conclusion | Ultrasonic array technology is effective for on-site testing and assessment of bolt conditions. |

By implementing regular inspections, operators can enhance the reliability and safety of construction machinery.

Proper Torque Application for Optimal Performance

Applying the correct torque is critical for ensuring the performance and safety of track bolts. Proper torque application prevents over-tightening or under-tightening, which can compromise bolt integrity. Cleaning fastener threads before applying torque ensures accurate measurements. Additionally, torque wrenches must undergo regular calibration to maintain precision.

- Calibration intervals, such as every 5,000 cycles or monthly, align with ISO standards.

- Digital torque wrenches require frequent calibration to prevent torque value drift.

- Age and usage can affect calibration, making routine checks essential.

These practices ensure that bolts remain securely fastened, reducing the risk of loosening under heavy loads.

Replacement Guidelines to Ensure Safety

Replacing track bolts and nuts at the right time is crucial for maintaining machinery safety. Operators should follow manufacturer recommendations and replace bolts showing visible signs of wear, such as cracks or corrosion. Using high-quality replacements, like those from Ningbo Digtech (YH) Machinery Co., Ltd., ensures compatibility and reliability.

Tip: Always use bolts that meet the original equipment specifications to maintain optimal performance and safety.

By adhering to these guidelines, operators can prevent unexpected failures and extend the lifespan of their machinery.

High-tensile track bolts play a vital role in ensuring the safety and efficiency of construction machinery. Their robust design enhances stability, prevents equipment failures, and reduces operational risks.

Note: Operators who understand their features and maintenance can maximize machinery performance and safety. Ningbo Digtech (YH) Machinery Co., Ltd. provides reliable solutions tailored to industry needs.

By prioritizing quality components, operators can achieve long-term reliability and operational success.

FAQ

What makes high-tensile track bolts essential for construction machinery?

High-tensile track bolts provide superior strength and durability. They secure critical components, ensuring stability and safety during heavy-duty operations in demanding environments.

How often should track bolts and nuts be inspected?

Operators should inspect track bolts and nuts regularly. Monthly checks or inspections after heavy use help identify wear or damage early, ensuring safety and reliability.

Can high-tensile track bolts be used across different machinery models?

Yes, high-tensile track bolts are compatible with various machinery models. Their versatile design simplifies maintenance and ensures reliable performance across multiple equipment types.

Post time: May-10-2025