Durability often depends on the material, design, and application of retainer pins locking pins. Retainer pins locking pins serve distinct purposes, making it crucial to evaluate their performance for specific tasks. Understanding the differences between these pins, along with related hardware like a Hex bolt and nut, ensures informed decisions when selecting a pin and retainer.

Key Takeaways

- Retainer pins work well for medium loads and are easy to install. They are great for setups that don’t last long.

- Locking pins are stronger and steadier, especially in tough situations. They keep things safe in important uses.

- Checking and oiling both types of pins often makes them last longer. This helps them work well over time.

Retainer Pins: Durability and Applications

What Are Retainer Pins?

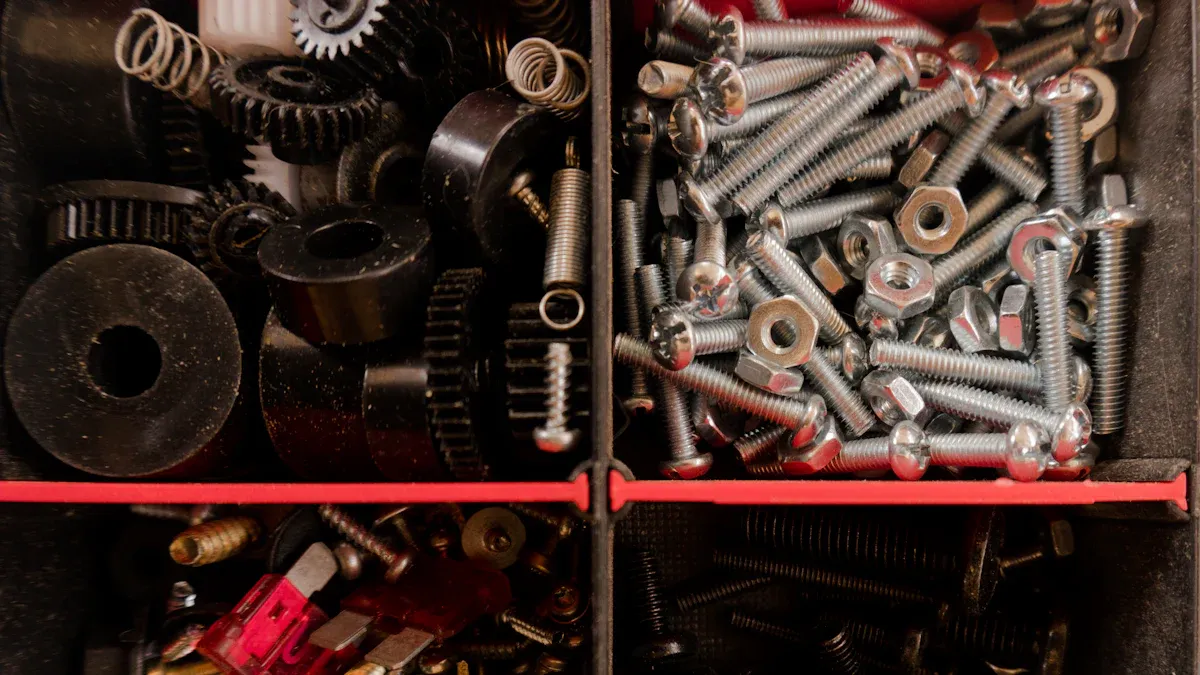

Retainer pins are small yet essential components used to secure objects in place. These pins typically feature a simple design, often consisting of a straight or slightly curved metal rod. They are inserted into pre-drilled holes to hold parts together or prevent movement. Retainer pins are commonly made from durable materials like stainless steel, carbon steel, or alloy steel, ensuring they can withstand significant stress during use. Their straightforward design makes them versatile and easy to install, even in complex assemblies.

Durability Factors of Retainer Pins

Several factors influence the durability of retainer pins. The material plays a critical role, as high-quality metals resist corrosion and wear over time. The pin’s diameter and length also affect its strength, with thicker pins offering greater load-bearing capacity. Additionally, the surface finish, such as zinc plating or galvanization, enhances resistance to environmental factors like moisture and chemicals. Proper installation ensures the pin remains secure, reducing the risk of premature failure. When used correctly, retainer pins provide reliable performance in demanding applications.

Common Uses of Retainer Pins

Retainer pins serve a wide range of purposes across industries. In automotive manufacturing, they secure components like axles and shafts. In construction, they hold scaffolding and heavy equipment parts in place. Agricultural machinery often relies on retainer pins to connect moving parts, ensuring smooth operation. These pins are also popular in DIY projects, where their simplicity and effectiveness make them a go-to choice for securing materials. Their adaptability makes them indispensable in various fields.

Locking Pins: Durability and Applications

What Are Locking Pins?

Locking pins are mechanical fasteners designed to secure components by locking them in place. Unlike retainer pins, locking pins often feature a spring-loaded mechanism or a ball detent system that ensures a firm hold. These pins are typically made from robust materials such as stainless steel, carbon steel, or titanium alloys, which enhance their strength and reliability. Their design allows for quick installation and removal, making them ideal for applications requiring frequent adjustments or replacements.

Durability Factors of Locking Pins

The durability of locking pins depends on several critical factors. Material composition plays a significant role, as stronger metals like titanium alloys and 316 stainless steel offer superior fatigue resistance. A study on fatigue testing revealed that larger diameter pins, exceeding 4.5 mm, demonstrated greater resistance to wear and tear during repeated stress cycles. Surface treatments, such as anodizing or galvanization, further enhance their resistance to corrosion and environmental damage. Additionally, the locking mechanism itself contributes to durability by preventing accidental disengagement, even under high loads or vibrations.

Common Uses of Locking Pins

Locking pins are widely used in industries where stability and safety are paramount. In medical applications, such as neurosurgical procedures, locking pins secure critical equipment like three-pin head fixation devices. Studies have shown that optimizing pin configurations can reduce risks of slippage and improve stability. In construction, locking pins are essential for securing scaffolding and heavy machinery components. They are also prevalent in aerospace and automotive industries, where their reliability ensures the safe operation of moving parts. Their versatility and robust design make them indispensable across various fields.

Retainer Pins vs. Locking Pins: A Detailed Comparison

Strength and Load-Bearing Capacity

Strength and load-bearing capacity are critical factors when comparing retainer pins and locking pins. Retainer pins, with their straightforward design, excel in applications requiring moderate strength. Their ability to hold components together securely makes them suitable for tasks like connecting axles or scaffolding. However, their load-bearing capacity depends on the material and dimensions of the pin. Thicker and longer retainer pins can handle higher loads, but they may not perform well under extreme stress or vibration.

Locking pins, on the other hand, are engineered for superior strength. Their robust construction and locking mechanisms provide additional stability. This design ensures that locking pins can withstand heavy loads and high-pressure environments without disengaging. Industries like aerospace and construction often rely on locking pins for critical applications where safety and durability are paramount. The spring-loaded or ball detent systems in locking pins enhance their ability to bear loads, even under dynamic conditions.

Resistance to Wear and Tear

The resistance to wear and tear varies significantly between retainer pins and locking pins. Retainer pins, often made from materials like stainless steel or carbon steel, resist corrosion and physical damage in standard conditions. Surface treatments such as galvanization or zinc plating further enhance their durability. However, in environments with constant friction or exposure to harsh chemicals, retainer pins may wear out faster.

Locking pins offer superior resistance to wear and tear due to their advanced materials and design. Titanium alloys and high-grade stainless steel used in locking pins provide excellent fatigue resistance. Additionally, the locking mechanism minimizes movement between components, reducing the risk of abrasion. Surface treatments like anodizing add an extra layer of protection, making locking pins ideal for long-term use in demanding environments.

Performance in Various Environments

Environmental conditions play a significant role in determining the performance of retainer pins and locking pins. Retainer pins perform well in controlled environments where exposure to moisture, chemicals, or extreme temperatures is minimal. Their simplicity and ease of use make them a practical choice for indoor applications or temporary setups.

Locking pins, however, are designed to excel in diverse and challenging environments. Their corrosion-resistant materials and secure locking mechanisms ensure reliable performance in outdoor, high-vibration, or high-temperature settings. For example, locking pins are commonly used in marine applications, where exposure to saltwater demands exceptional corrosion resistance. Their ability to maintain stability under varying conditions makes them a preferred choice for industries requiring high reliability.

Tip: When selecting between retainer pins and locking pins, consider the specific environmental conditions and load requirements of your application. This ensures optimal performance and longevity.

Practical Tips for Choosing Between Retainer Pins and Locking Pins

Application-Specific Recommendations

Selecting the right pin type depends on the specific requirements of the application. Retainer pins are ideal for tasks that demand simplicity and ease of use. Their straightforward design makes them suitable for temporary or semi-permanent setups, such as securing scaffolding or connecting lightweight components in machinery. Industries like agriculture and construction often rely on retainer pins for their adaptability and quick installation.

Locking pins, however, excel in applications requiring enhanced stability and safety. Their robust locking mechanisms make them indispensable in high-stress environments, such as aerospace, automotive, and medical fields. For example, locking pins are commonly used in equipment that undergoes frequent adjustments or experiences significant vibrations. Their ability to maintain a secure hold under dynamic conditions ensures reliability in critical operations.

When choosing between retainer pins and locking pins, consider the following factors:

- Load Requirements: Retainer pins work well for moderate loads, while locking pins handle heavy-duty applications.

- Environmental Conditions: Locking pins offer superior corrosion resistance, making them suitable for harsh environments.

- Frequency of Adjustments: Locking pins are better for applications requiring frequent disassembly or repositioning.

Pro Tip: Consult with a trusted supplier like Ningbo Digtech (YH) Machinery Co.,Ltd. to ensure the selected pin type meets your specific needs.

Maintenance and Longevity Tips

Proper maintenance extends the lifespan of both retainer pins and locking pins. Regular inspections help identify signs of wear, corrosion, or damage. For retainer pins, ensure they remain securely seated in their designated holes. Loose or improperly installed pins may compromise the stability of the assembly. Cleaning the pins periodically removes dirt and debris, which can cause premature wear.

Locking pins require additional attention due to their complex mechanisms. Lubricating the locking mechanism prevents stiffness and ensures smooth operation. Inspect the spring-loaded or ball detent system for any signs of malfunction. Replace worn-out components promptly to maintain optimal performance. Surface treatments, such as galvanization or anodizing, should remain intact to protect against environmental damage.

Note: Store unused pins in a dry, clean environment to prevent rust or contamination. Proper storage practices enhance the longevity of both retainer pins and locking pins.

By following these maintenance practices, users can maximize the durability and reliability of their hardware. Whether using retainer pins locking pins, proper care ensures consistent performance over time.

Both retainer pins and locking pins offer unique advantages depending on the application. Retainer pins excel in simplicity and adaptability, making them ideal for moderate load-bearing tasks. Locking pins provide superior durability and stability, especially in high-stress environments.

Recommendation: For temporary setups or lightweight components, retainer pins are a practical choice. For critical applications requiring enhanced safety and reliability, locking pins deliver unmatched performance. Consult Ningbo Digtech (YH) Machinery Co.,Ltd. for expert guidance on selecting the right pin type for your needs.

FAQ

What is the main difference between retainer pins and locking pins?

Retainer pins secure components with a simple design. Locking pins use mechanisms like spring-loaded systems for enhanced stability and safety.

Can locking pins handle extreme environments better than retainer pins?

Yes, locking pins excel in harsh conditions due to corrosion-resistant materials and secure locking mechanisms.

How can users ensure the longevity of retainer and locking pins?

Regular inspections, proper installation, and cleaning prevent wear. Lubricating locking mechanisms ensures smooth operation and extends durability.

Post time: May-02-2025